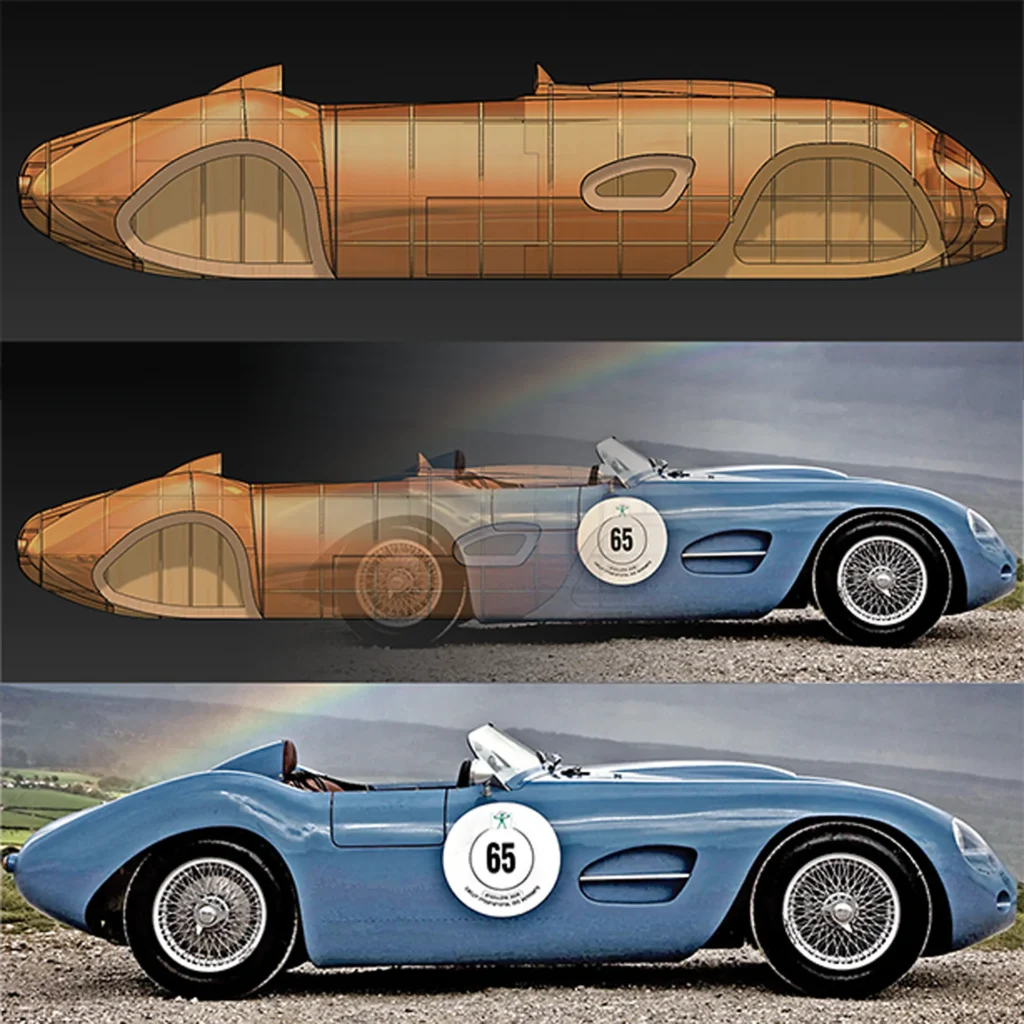

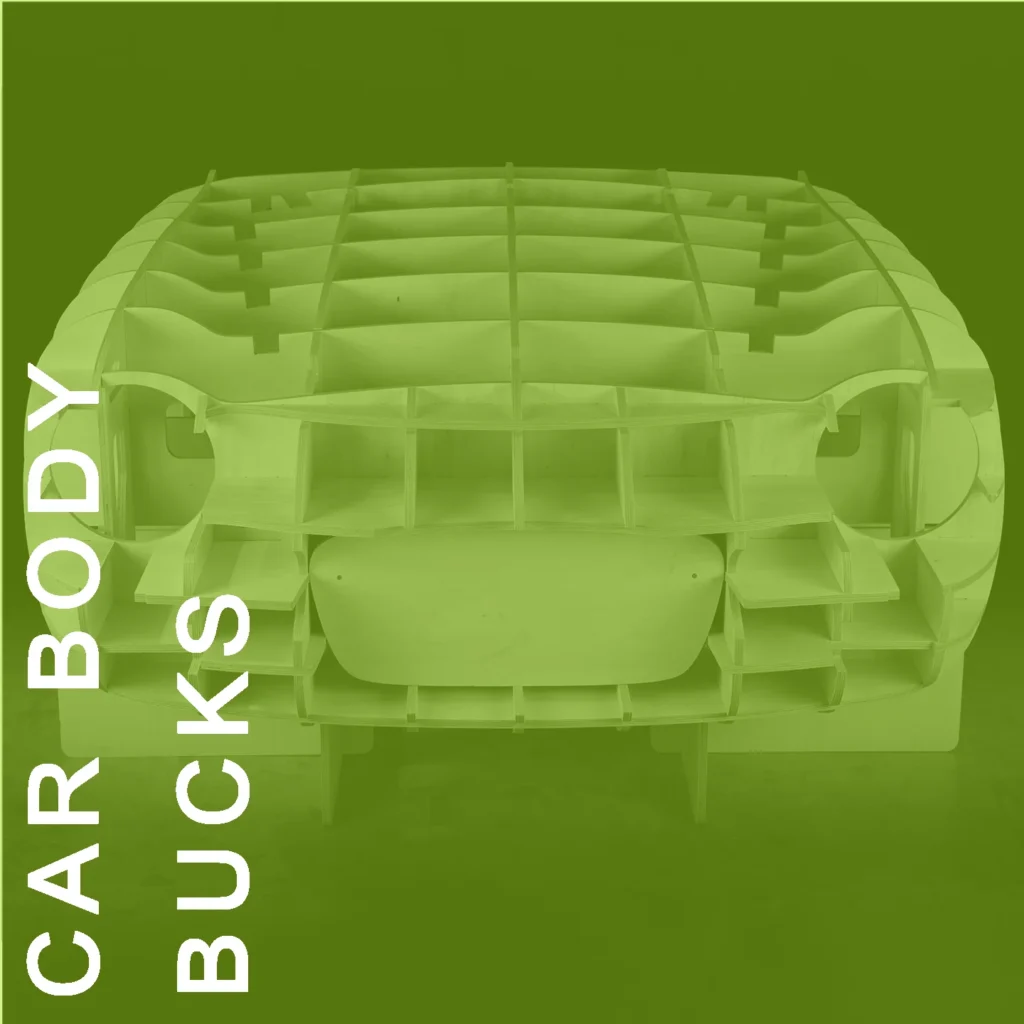

Forte Vision car body bucks are the product of over a decade of experience. This experience enables us to create designs using the optimum amount of material, that work for the metal worker, are designed in consultation with your chosen metal worker and that have material in the correct place.

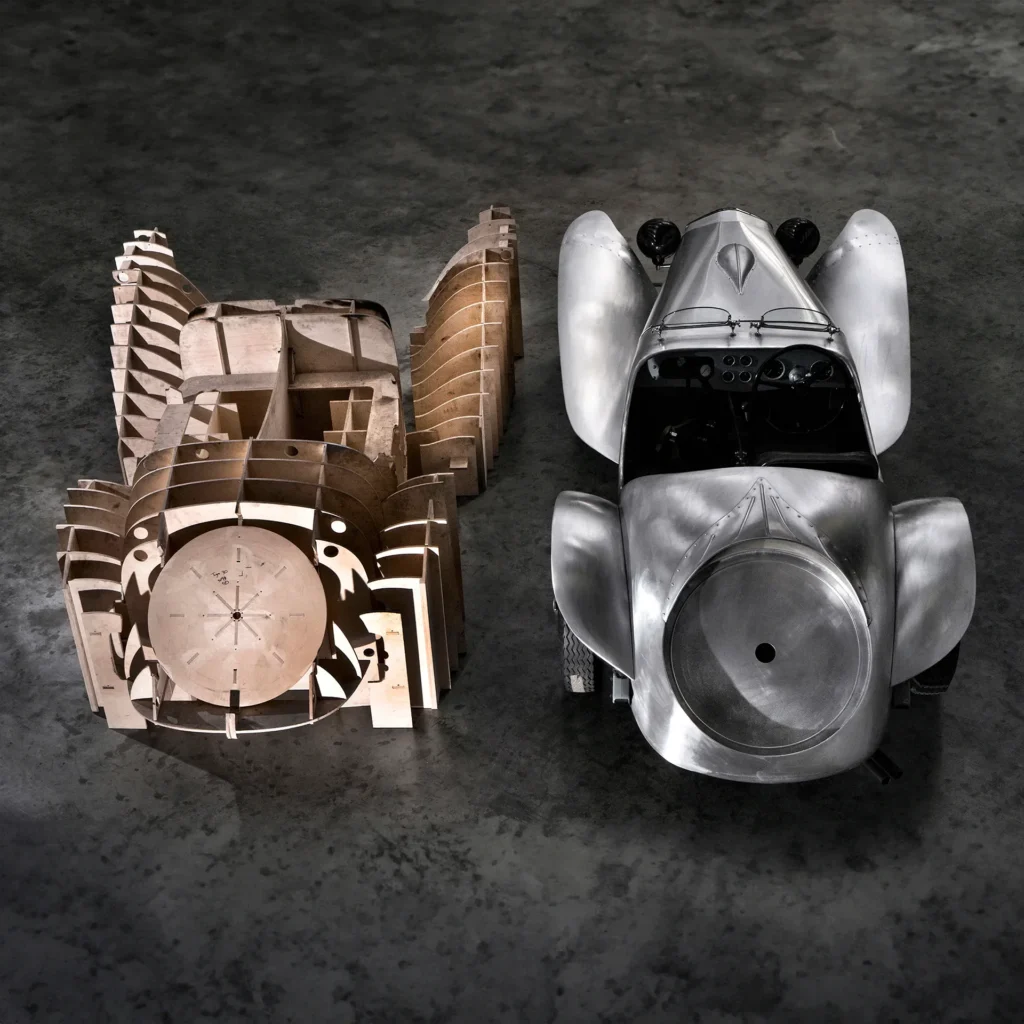

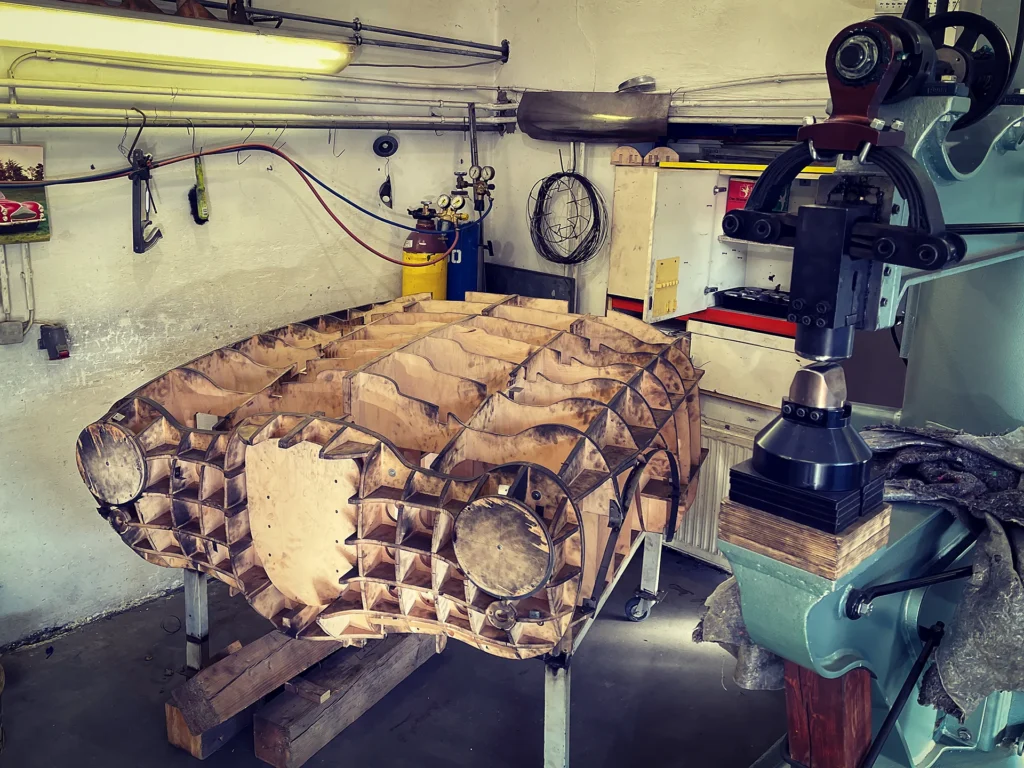

Your buck can be of section or egg crate design or hammerform and any hybrid in between. We will counsel you on the best options for your project and production volume.

We do not sell plans. This is because every buck is bespoke, since all metal workers have different methods and requirements. Additionally, although we can work from scale models, our preferred method is to work from scan data of original cars or plans from period. We know that our competitors use models or 3D models bought from the web. We have explored this option and having compared these against real vehicles we have scanned, the accuracy of the model method is typically unacceptable.

DELIVERED WORLDWIDE

Forte Vision car body bucks:

- Bucks can be plywood or stainless steel.

- Machining of a buck is completed to our own specification.

- Internal corners have a feature added to ensure the parts fit together perfectly. No manual filing required of hundreds of joints.

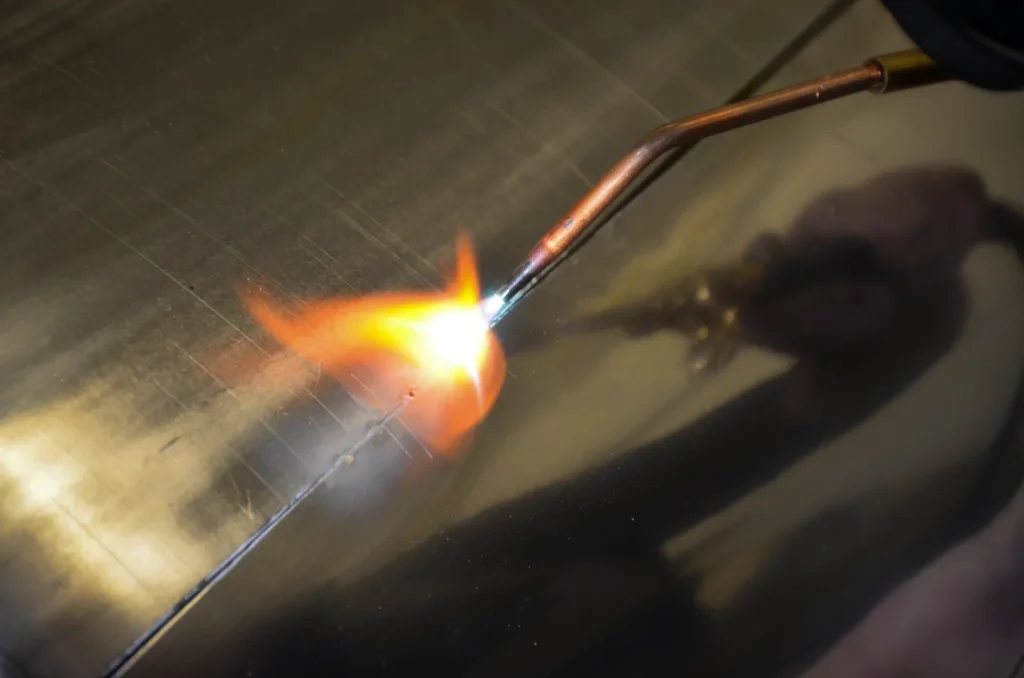

- Hammer form elements can be added within the buck itself or as separate items. 3D printed and machined options available. Material used depends on client requirement and manufacturing method.

- Allowance is made for clamps to be added and areas to be removed for body understructure to be made on the buck.

- Forte Vision bucks typically use up to 40% less material than our competititors due to efficient design and manufacturing process.

- Bucks are designed so a metal worker can see behind the panel to check fit.

- Bucks have material where required. We do not design with solid plywood sheets added at right angles filling the whole car body shape with material.

- We do not use models downloaded from the web, scale models or toys as the base data for a buck. The data can help, sometimes, but it always demands a lot of checking and work to refine even if the quality is worth working with.

- Forte Vision car body bucks have three main sections as a typical minimum. Regularly, Forte Vision bucks have ten sections. Why? To assist manufacture and enable work to be undertaken on a bench as opposed to ground level. Your metal worker will be pleased.

- The surface of the car is inset, typically 1.5mm – 2mm but you can choose, so that there is no “growth” of the car compared to an original vehicle.

- Specific parts of a car, for example a wing or bonnet, can be created as a buck in isolation. Design are future-proofed so further areas can be added at future dates.

- Forte Vision has 3D laser scanned, or designed from scratch, over 400 cars. Of this sample, we have, to date, over 120 scans that we have collected on our own account. Please ask if you require a buck for a particular car. We may have it already.

- Known parts, for example a windscreen, can be integrated at the design stage, so you can be assured parts will fit with known tolerance and gapping when the car body is made.

- We deliver and install bucks all over the planet. The end product is not a pile of wood for you to assemble.

- Price(s) are agreed at the outset.

- Changes, with the assumption that the design is gravitating towards a known goal, are allowed up until commitment to manufacture.

- Often our bucks are used as an art installation, a car sculpture, after a project is completed.

- Bucks are designed to flat pack after use for compact storage.

- Typically, over fifty and most often over one hundred images of the car body are taken as reference material for your project.

- Pictures can include, if required, images of tape measures or digitial calipers against features. Why? Because some people like to check with images as opposed to a computer.

“Very good company. We have had excellent work provided”

Ian Pitney – Pitney Restorations

Optional extras:

- Scan of your chassis and/or vehicle body for car body buck fitting and comparison purposes.

- Wing and aperture edging and arch strips to further assist build.

- Buck to be designed to fit over a chassis. Enables design refinement and proof of concept before manufacture in metal begins.

- Engraving of the buck part numbers for each part of the buck assembly.

- Stand including castors.

CARS CREATED FROM OUR 3D SCANS, BUCKS AND/OR BODY DESIGNS:

A table showing a selection, some are not mentioned due to non-disclosure obligations, of the car body bucks Forte Vision has created.

| MODELS – BUCK DESIGNS | ||

| AC Cobra | Alfa Romeo 2900B | Alvis Beetle Back |

| Alvis TD21 Graber | Alvis TC21 Special | Aston Martin DB2 |

| Aston Martin DB2/4 | Aston Martin DB5 Saloon | Aston Martin Zagato |

| Austin A35 Pickup | Austin 7 racer | Ballot 2 Litre re-creation |

| Bentley Continental | Bentley Bensport La Sarthe | Bentley Petersen |

| Bentley 2 seat special | Bentley single seat special | Bugatti Type 35 |

| Cobra Daytona | Cunningham CR4 | Ferrari 250 California |

| Ferrari 250 GTO | Ferrari 400i special | Ferrari 275 GTB Special |

| Frazer-Nash Targa Florio | Hotrod – 1932 | Jaguar C-Type |

| Jaguar D-Type | Jaguar E-Type XKE custom | Jaguar Hochberg |

| Jaguar XJ13 re-creations | Jaguar XK120 Coupe | Lancia Aurelia B24 Spider |

| Lancia Flaminia | Lister Costin | Lister Knobbly |

| Maserati 250F | Maserati Mistral | Mercedes 1908 GP |

| Mercedes Rennsport Transporter Blue Wonder | Mitchell Special MKII | Porsche 356B Coupe |

| Porsche 550A | Renault 1913 Boat tail | Sterling Speedster |

| Steady Special | The Blue Car |

INTELLECTUAL PROPERTY (IP)

The full explanation of our view is here. IP is a “dry” but essential concept to understand and Forte Vision would class this link as essential reading.

WHAT IT IS ALL ABOUT. CREATING CAR BODY BUCK TOOLING THAT WORKS. TIME AND AGAIN.

Lancia Aurelia B24 Spider case study.

CAR BODY BUCKS

Prices start from £800 for a parts or section of bodywork. A car buck starts from £4000.

All buck prices include 3D scanning (if required), design, manufacture, delivery and assembly.

Assembly can occur most places worldwide.

Like what you see? Then please complete the form below to start your bespoke car/body buck journey.

FEATURED IN

Octane – The Automobile – Road & Track – Develop3D – Classic & Sports Car – Bugatti brochure

SHOWN AT

Goodwood Revival – Goodwood Festival of Speed – London Concours – Hampton Court Concours – Pebble Beach Concours d’Elegance – Rotunda / Royal Automobile Club – International Historic Motoring Awards – REAL2015 – Techno Classica – Retromobile

DELIVERED BUCKS AND DESIGNS TO

UK – France – Belgium – Holland – Germany – Italy – Ireland – South Africa – USA – Australia – Canada – Switzerland

WORKED ON SITE AT

UK – Frankfurt – Verbania – Limerick – Den Helder – Seattle – Salt Lake City – New York – Los Angeles – Las Vegas – Philadelphia – Birmingham (Alabama) – Indianapolis – San Francisco – Washington – Douglas Isle of Man – Johannesburg – Geneva – Roggliswil – Berlin – Paris – Nice

NOTABLE PLACES WHERE WORK WAS UNDERTAKEN AND/OR DELIVERED

Beaulieu National Motor Museum – BRE: Peter Brock Designs – Simeone Museum – Indianapolis Motor Speedway Museum – Thornley Kelham – Hall & Hall – Allard Cars – Shapecraft – Aston Martin Works – Mitchell Motors – Washington DC Auto Show – Geneva International Motor Show – The Bugatti Trust – Jim Stokes Workshops (JSWL) – Vintage Racing Green – Kia Design Center – Mouland & Yates – Williams Racing – Duncan Hamilton

The legals:

Forte Vision is not approved, associated, endorsed, sponsored or, in any way, affiliated with any of the businesses mentioned on this website. Any external business names mentioned are the trademarks of their respective holders. Any mention of trademarked names, businesses or other marks is for the purpose of reference only.